Precaution of Using Permanent Lifting Magnet

(1) During the use of permanent lifting magnet, it should be prevented from knocking and bumping to keep the performance. For long-term use, if the suction surface is uneven, the surface can be grinded, but the cumulative amount must not exceed 5mm.

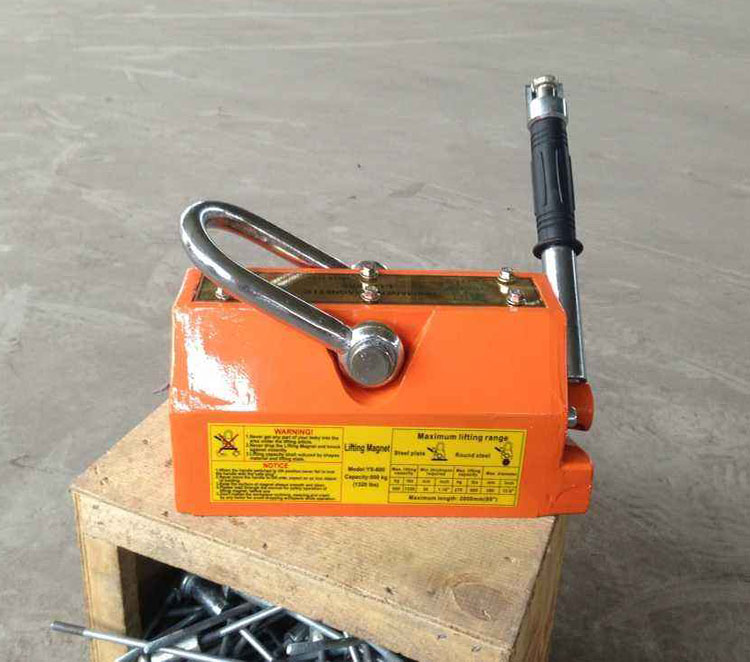

(2) The handle cannot be pulled until the bottom of the permanent magnet lifter pressed to the workpiece. The workpiece shouldn't be too thin and too heavy.

(3) During the lifting process, it is strictly forbidden to stand or cross under the workpiece held by the permanent magnet.

(4) The holding surface of permanent lifting magnet should be always clean and flat; if there is oil, it should be wiped clean.

(5) Regularly check the the slide button and the positioning pin at the top of the handle to ensure reliable locking and safe use.

(6) After the workpiece is hung, the driving should ensure smooth walking, so as to avoid excessive shaking, impacting, and damage. If there is any cracked, broken or damaged inside, contact the company for repair,do not repair it yourself.

(7) The permanent lifting magnet must be inspected every two years from the date of use to ensure safety.

(8) The operation of permanent lifting magnet should also strictly implement the national crane safety operation procedures.