Lifting hoists

The lifting hoists are industrial lifting devices that use wire ropes or chains in order to lift and / or maneuver a load. They can be placed in a fixed position or on special designed trolleys to ensure lateral movements of the load. The hoists can also be attached to cranes or other lifting devices.

Depending on their operating principle the lifting hoists are divided into manual, electric, hydraulic or pneumatic hoists. In order to properly choose your requested hoist, please take into account the following:

A. The weight of the load: it’s strictly forbidden to use a hoist with a lower WLL (Working Load Limit) than the weight of the load it needs to lift;

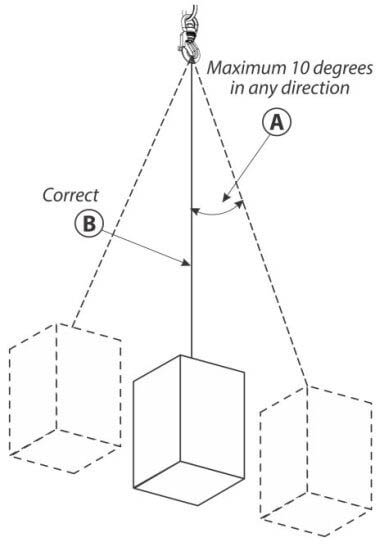

B. The shape and sizes of the load: at all times the positioning of the hoist must be directly above the center of mass of the lifted load;

C. Maneuvering space: you always need to take into account the free space needed around the load, as well as the lifting height of the load;

D. The features of the hoist: usage frequency, lifting / lowering speed, maneuvering accuracy, etc.;

E. The hoist’s working cycle:

the number of operations completed per hour;

the total number of operations completed per shift;

the number of shifts per working day;

the maximum number of starts / stops per hour;

the average weight of the lifted loads;

the maximum weight of the lifted load;

the lifting height.

The hoist operators need to be properly instructed about the equipment they operate on and it is very important to be accustomed to other types of lifting equipment as well. Unfortunately, most accidents are due to the lack of proper training of the lifting operators that sometimes are oblivious to the dangers to which they expose themselves and those around them. Before you begin lifting a load please make sure that:

the load you have to lift does not exceed the hoist’s rated WLL;

the hoist is secured in its holding place;

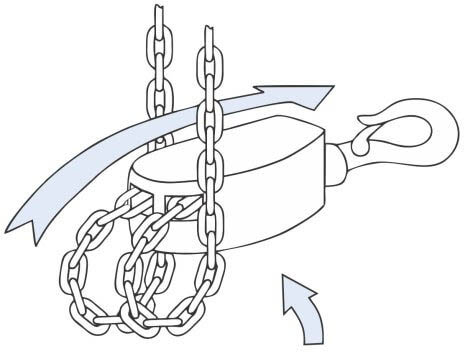

the hook is not twisted around the lifting chain(s) - for the hoists that have multiple lifting chains (see fig. 1);

the hoist is positioned directly above the center of mass of the load to be lifted (see fig. 2);

the lifting chains / wires are properly attached to the hook and do not show visible fatigue signs or worn out traces;

during the lifting operation make sure there are no persons under the load or near the load’s moving direction (if applicable);

the lifting of the load will be performed smoothly, without any swinging;

the hooks do not show any deformations and the wear signs are within safety limits.

Prior to any use the hoist must be visually inspected by the operator in order to find any cracks, deformations or any other flaws that might affect its proper use or would present a safety hazard for the operator or any other people. If such problems are spotted and the hoist’s condition is altered it is forbidden to use it and the safety inspectors need to be duly informed.

It is advisable to perform maintenance tasks on the hoists both after the completion of each using cycle as well as on a scheduled basis by authorized trained personnel. Before passing along any hoist to be used take the time to perform a minimum training for the operators in order to get them acquainted with the equipment and also hand them the instructions manual that accompanies the product.