Instructions for use and maintenance of chain hoist

In modern industrial production, the storage and transportation of products are inseparable from hoisting operations. The electric hoist provides great convenience for lifting operations and greatly improves the efficiency of operation. In recent years, the use of electric hoists is increasing rapidly, the maintenance also becomes important. Dealing with various faults in time has become an important part of production.

Definitions

Abnormal operating conditions: Environmental conditions that are unfavorable, harmful or detrimental to the operation of a hoist, such as excessively high or low ambient temperatures, exposure to weather, corrosive fumes, dust-laden or moisture-laden atmospheres and hazardous locations.

Designated person: A person selected or assigned by the employer or the employer's representative as to perform specific duties.

Heavy service: Service that involves operation within the rated load limit, which exceeds normal service.

Normal service: Service that involves operation with randomly distributed loads within the rated load limit or uniform loads less than 65% of the rated load for not more than 15% of the time for manually operated hoists and 25% of the time for electric or air-powered hoists.

Severe service: Service that involves normal or heavy service with abnormal operating conditions.

Overhead Hoist Inspection Requirements

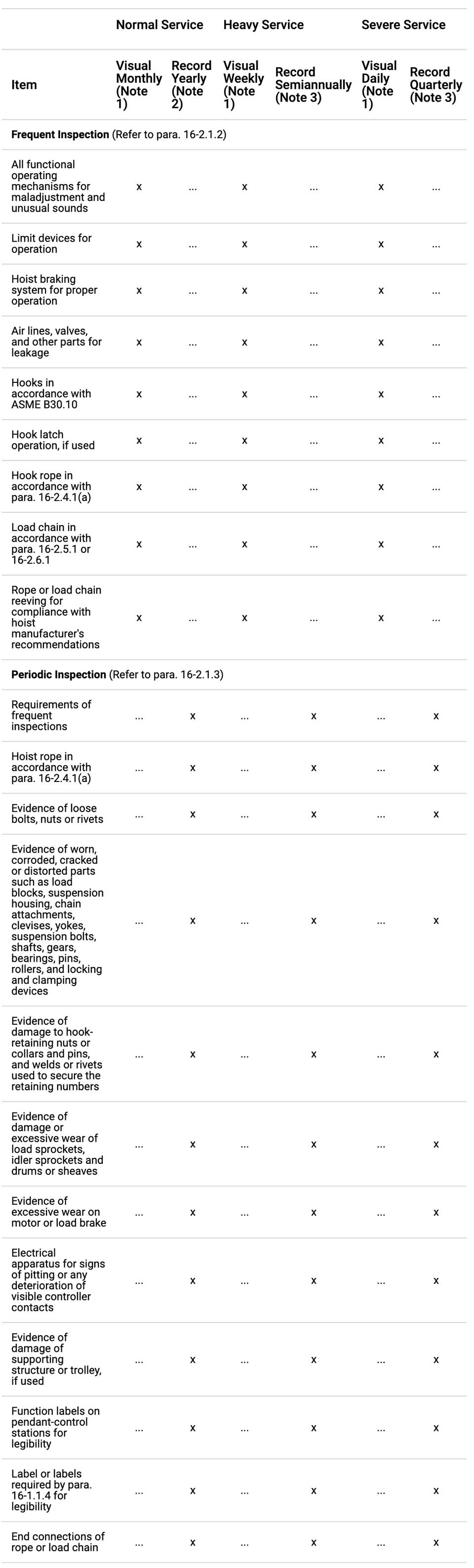

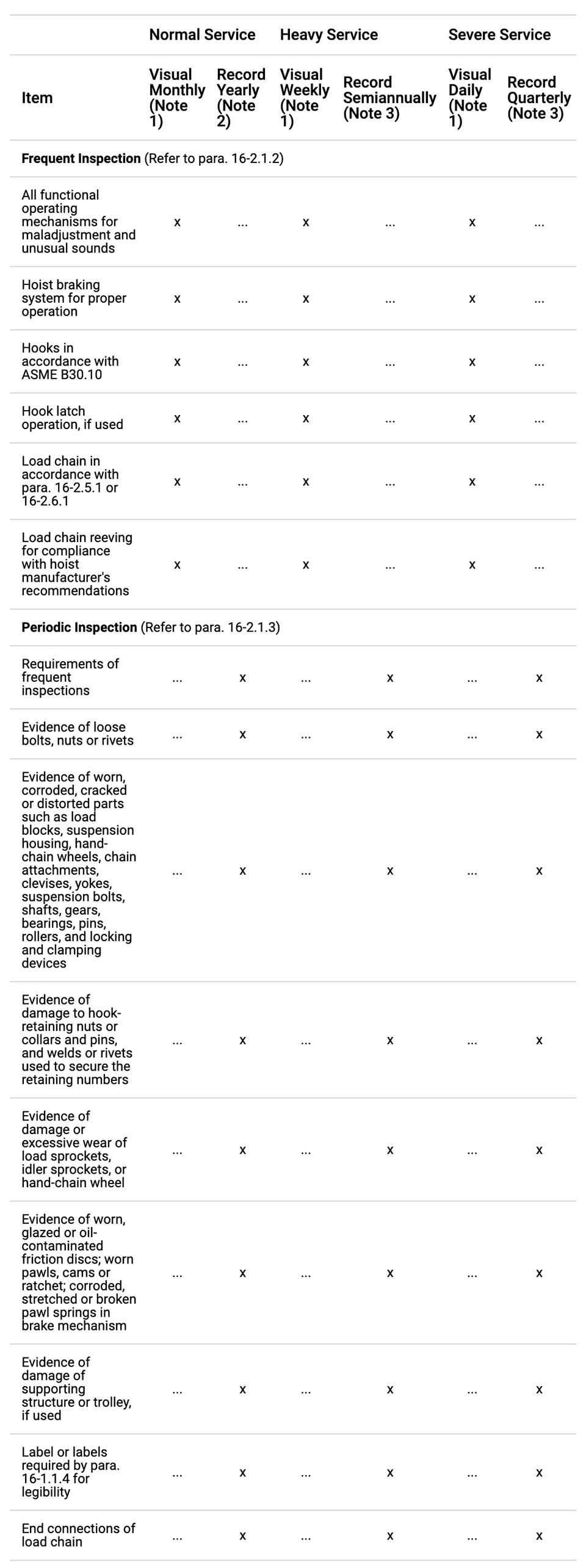

A designated person should inspect hoists before their initial use and on regular intervals to verify compliance with ASME/ANSI B30.16. The specific inspection requirements are found in Table 1 and Table 2 of the B30.16 standard, which are reprinted below with written permission from ASME. The inspections are classified into frequent inspections that do not require documentation and periodic inspections that require documentation. The interval between inspections depends on the service of the hoist. The owner's manual specific to the hoist is another good source for inspection and maintenance requirements and should be based on the requirements of this standard.

Table 1 - Inspection for Hand Chain-Operated Hoists

Notes:

By operator or other designated person with records not required.

Visual inspection by a designated person making records of conditions to provide the basis for a continuing evaluation.

As in Note 2 unless conditions indicate that disassembly should be done to permit detailed inspection.

Reprinted from ASME B30.16-2003, by permission of The American Society of Mechanical Engineers. All rights reserved.

Table 2 - Inspection for Electric- or Air-Powered Hoists